Recommended CO2 Grades for use as a refrigerant in a CO2 Booster system

Due to global supply chain challenges, there has been a shortage of Carbon Dioxide (CO2 ) available for refrigerant grade CO2 as well as for gas cylinders. This bulletin is designed to provide Dover Food Retail’s recommendations and guidelines for using the appropriate grade of CO2 (R744) as a natural refrigerant.

CO2 is produced as a byproduct of several manufacturing processes such as the formation of hydrocarbons or various distillation and fermentation processes. After CO2 gas has been isolated it is purified into various levels, removing impurities, moisture, and non-condensable gases resulting in different grades of CO2 for various applications.

Examples of various grades of CO2 are shown below:

Common Grades of CO2

Industrial Grade – 99.5%

Bone-Dry Grade – 99.8%

Anaerobic Grade – 99.9%

Coleman (Instrument) Grade – 99.99%

Research Grade – 99.999%

Ultra-Pure Grade – 99.9999%

Coleman (Instrument) Grade CO2 contains less than 0.01% non-condensable gases and moisture (99.99% pure) is the recommended grade of CO2 for commercial refrigeration systems.

Key factors to note:

• CO2 used in commercial refrigeration systems must be of a purity level high enough to prevent the introduction of non-condensable gases into the system.

• A build-up of these gases can block the heat transfer surface and cause inefficient operation or malfunction of the system.

• Non-condensable gases that may be trapped in the system can be removed by using an available access valve in the system to vent off the non-condensable gases.

Below shows typical Coleman (Instrument) Grade impurities:

Specifications of Coleman Grade CO2 impurities

Minimum Purity of CO2 – 99.99%

Nitrogen N2 – < 50 ppm

Oxygen O2 – < 20 ppm

Water H2O – < 10 ppm

The introduction of a lower-grade CO2 (99.99%) with purity levels less than those of the Coleman Grade is not recommended and should only be done in emergencies. The use of a lower-grade CO2 may result in decreased system performance and require specific procedures to purge non-condensable gases from the system.

In emergency or shortage situations CO2 grades of lower purity levels such as “Industrial Grade” and “Bone Dry Grade” should take the following precautions:

1) Include a filter drier in the line as part of the charging process

2) Thoroughly check for non-condensable gases, which may get charged into the system, and execute specific procedures to purge non-condensable gases from the system

The use of Carbon Dioxide of a higher level than Coleman Grade CO2 (99.99%) is acceptable through typically not cost-effective nor readily available in the quantities needed for charging an entire system.

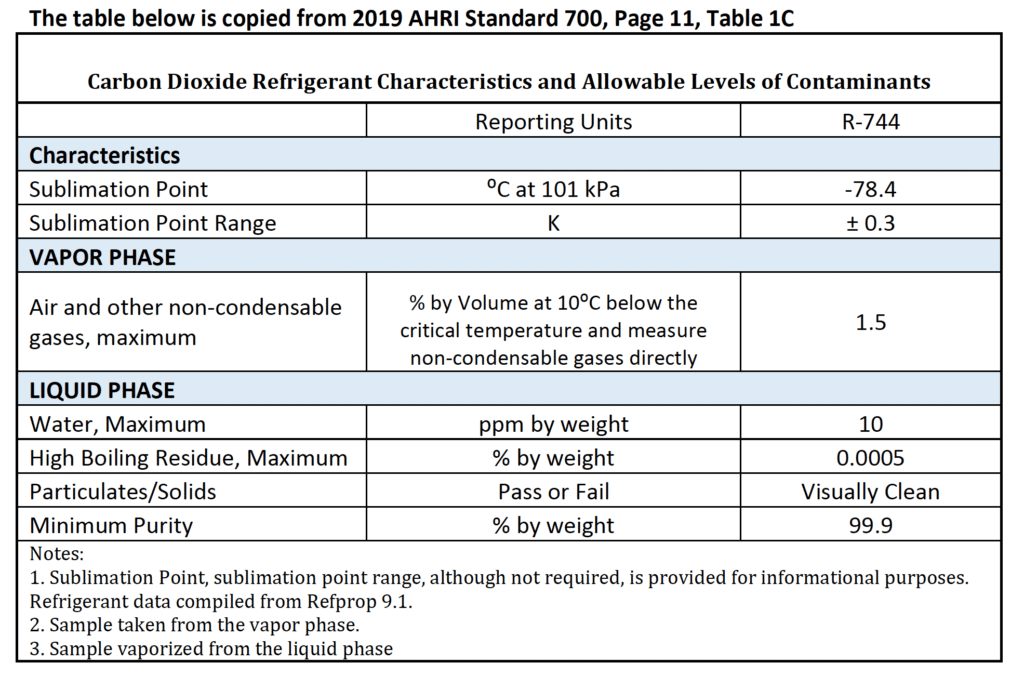

To ensure that the refrigeration system operates properly the purity of the CO2 (R-744) utilized in the R-744 refrigeration system must meet certain standards as specified below:

Warning: Some CO2 gas suppliers offer a “cap-charge” of helium or other gases for liquid cylinders which increases tank pressure to speed the charging process – DO NOT accept any cylinder with this cap-charge – use only cylinders that are PURE CO2 . The use of cylinders with a cap charge is likely to introduce large amounts of non-condensable gases, render the system inoperable, and require purging, evacuation, and recharging of the entire system.

To determine if a cylinder has a cap-charge, measure the tank pressure using a regulator and compare this with the saturation pressure at the approximate storage temperature of the tanks – tanks with a cap-charge will have a pressure significantly higher (>200 psig) than the corresponding saturation pressure.